Material Properties

Material properties are defined on the Material Properties Spreadsheet and are then referred to as you build your model elements. You can use up to 500 materials in a single model.

Material Properties Spreadsheet

The Material Properties Spreadsheet records the material properties to be used in the model and can be accessed by selecting Materials from the Data Entry section of the Explorer panel. The entries are described below:

Click on image to enlarge it

The materials shown are the program defaults. However, you can change these and also add as many other materials as you need. You can then save your preferred materials as the default materials by clicking the Save as Defaults button on the Spreadsheets tab.

Label is the material label you wish to use to describe the entered material properties. This label is how you will reference the set of properties later when defining model elements.

E is the Young's modulus that describes the material stiffness.

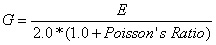

G is the shear modulus and can be left blank if you would like it calculated automatically. The equation for "G" is:

Nu is the Poisson's ratio. Besides being used for the "G" calculation, this value is also used for shear deformation calculations. The value of the Poisson's ratio may not exceed '0.5'.

Therm is the coefficient of thermal expansion and is entered per 10^5 (100,000) degrees.

Density is the material density and is used in the calculation for self weight. This density, times the area, gives the self weight per unit length for members; density times slab volume gives the total weight of a given slab.

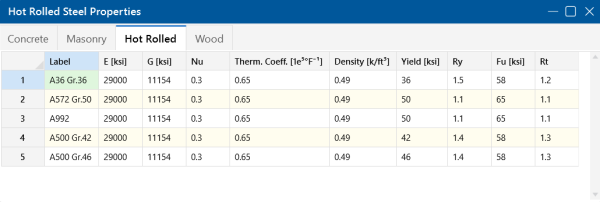

Hot Rolled Specific Material Data

The Hot Rolled tab records a number of hot rolled steel specific material properties that do not apply for the other materials. These entries are described below:

Click on image to enlarge it

Ry is the ratio of the expected yield stress to the specified minimum yield stress.

Fu is the specified minimum tensile strength.

Rt is the ratio of the expected tensile strength to the specified minimum tensile strength Fu, as related to overstrength in material yield stress, Ry. Rt is currently not used by the program.

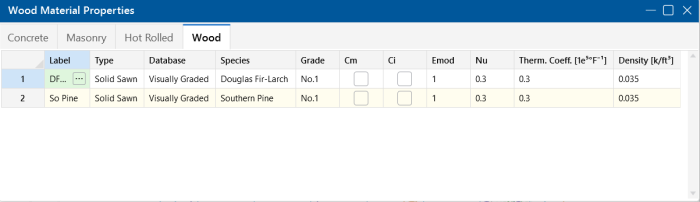

Wood Specific Material Data

The Wood tab records a number of wood specific material properties that do not exist for the other materials. These entries are described below:

Click on image to enlarge it

Type – Currently, there are four wood types available: Solid Sawn, Glulam, SCL (this includes LVLs) and Custom.

Database – Based on your Type selection, the Database menu will filter to the appropriate databases.

Species – Based on your Database selection, the Species menu will filter to the appropriate databases. This is the wood species designation from your selected design code.

Grade is the wood grade designation from your selected design code. This has a drop-down list where you can select the appropriate grade.

The Cm check box determines if the wet service / moisture content factor should be applied. If you put a check in the Cm field, the appropriate factors will be applied to the allowable stresses and Young’s Modulus (E).

The Ci check box determines if the incision factor should be applied. If you put a check in the Ci field, the appropriate factors will be applied to the allowable stresses and Young’s Modulus (E).

Emod is a factor that is applied to the Young’s modulus modifier to reflect the NDS Appendix F criteria. This is not applicable to the CSA O86 design code.

Commercial Species Groups

When either the NDS 05/08, 12, 15, 18 or 24 wood design code is selected, the Solid Sawn Species menu lists two new species that are not specifically shown in the NDS code. These are the Commercial Species Group I - DF/SP and Commercial Species Group II - HF/SPFe Fir. These are meant to be simplified groupings of the most commonly used wood species. It is meant to simplify the selection process for wood member design in the United States.

The design values for Group I take the NDS allowable stress values for two of the most widely used species (Doug Fir-Larch and Southern Pine) and uses the lower bound allowable stress value for each size and grade. To verify exactly what base allowable stress values were used, you can review the properties in the Shape Selection dialog.

Similarly, the design values for Group II take the allowable stress values for Hem Fir and Spruce-Pine-Fir and use the lower bound allowable stress values for each size and grade. You can also verify the base allowable stress values used for this selection in the Shape Selection dialog as well.

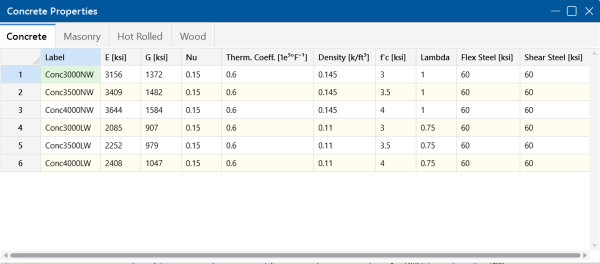

Concrete Specific Material Data

The Concrete tab records a few concrete specific material properties that do not apply for other materials. These entries are described below:

Click on image to enlarge it

f'c is the concrete compressive strength used for concrete design.

Lambda, λ is the lightweight concrete modification factor. This factor only applies to the ACI 318-19 ACI 318-14, ACI 318-11, ACI 318-08 and CSA A23.3-04 codes. For all other codes, the Density value of the material determines any strength reduction. The program automatically calculates the correct value if it is left blank. Only values between 0.75 and 1.0 will be considered.

Flex Steel is the reinforcement yield strength for flexural bars.

Shear Steel is the reinforcement yield strength for shear bars.

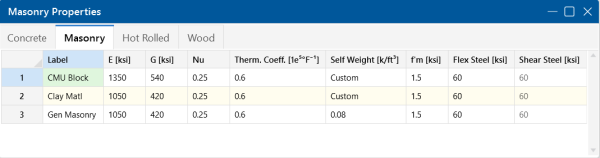

Masonry Specific Material Data

The Masonry tab records masonry specific material properties that do not apply for other materials.

Click on image to enlarge it

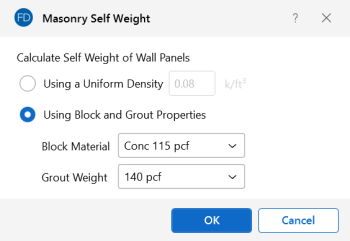

Masonry Self Weight can be accounted for by two different methods. Entering a number for the density will result in masonry walls which have a self weight equal to that density multiplied by the wall cross-sectional area. Otherwise, click within the cell and select  to launch the masonry self weight dialog:

to launch the masonry self weight dialog:

Click on image to enlarge it

Set the Using Block and Grout Properties option to have the program automatically calculate the self weight of the wall using the weights from table B3 of the Reinforced Masonry Engineering Handbook (RMEH). The self weight will be listed as Custom.

f'm is the masonry compressive strength used for masonry design.

Flex and Shear Steel are the rebar yield strengths for flexural and shear bars used to reinforce the masonry.

- Masonry Shear Steel is automatically set to the Flex steel strength.

- Masonry materials are only used for walls in wall footings. For more information, see the Wall Footing Definitions Spreadsheet.

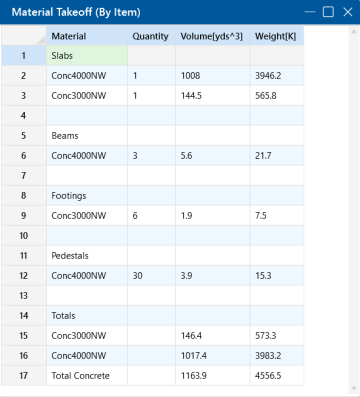

Material Takeoff

Access the Material Takeoff spreadsheet by selecting it from the Results menu.

Click on image to enlarge it

This spreadsheet shows material takeoff information for each material and element type in the model. For each material, the element types are listed with the total quantity, volume and weight.

The weight is the sum of the self-weight for all elements

- This Material Takeoff report is independent of the loads applied to the model, i.e. the applied loads do not influence this report.

- Beams that frame into a footing or pile cap will show the beam stopping at the location of the element. However, for material takeoff concerns, the entire length of beam (all the way to the end node corresponding to the footing/cap pedestal) is considered.